Tristate Machinery Dismantlers Forum > MICHIGAN

> Machine Parts

> New

> Sheet line, up to 53" wide by .40" thick, co ex, 2003

Sheet line, up to 53" wide by .40" thick, co ex, 2003

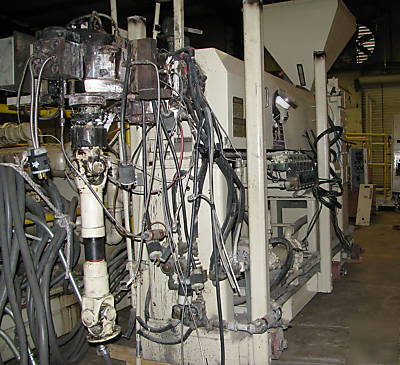

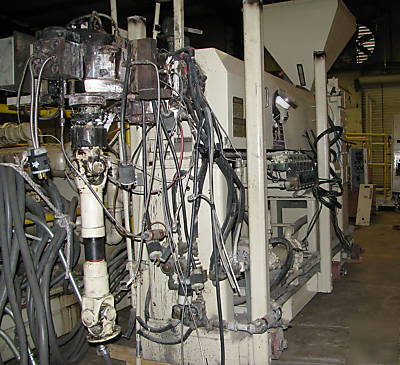

Sheet Line Co-Extruders up to: 53" (1350mm) width by 0.400" (10mm) thickness

mfg. CINCINNATI MILACRON system upgraded by Mfg in 2003 (originally built 1998)

Main Extruder single screw, 6 diameter, 500 hp, 36:1, electric heat and water cooled.

Co-Extruder: single screw, 2.5" diameter, 75 hp, 36:1, electric heat and water cooled.

Both extruders are vented have screen changers and gear pumps.

Complete system: Calendars (chilled rollers) embossing either textured or smooth, Former, coolers conveyer, puller, Guillotine (shear), winder for thin film or conveyer to stacking table for sheets. Last ran September 2008 running crumb rubber for shop floor and truck mats. Currently stored in warehouse located in South Carolina, USA with closet Airport code CLT (Charlotte, NC USA).

1.) Extruder Main: CINCINNATI MILACRON, Single Screw 6" diameter, Model: E50146

- Gearbox, Flender, Type: SDNE 360, Serial# D22-203-665-13-1, Rating 1053hp, output 148.3 RPM's, Ratio 11.8041

- 6" two (two) Control Panel requires, 800amp-Drive, 500amp-heater other, 480v/3p/60hz

- L:D 36:1 (216" screw processing length)

- Vent side mount located L:D 20:1 (122" length downstream process)

- Screen Changer by Polymer Systems, Inc. (PSI) 6" slide plate Model:HSC-60

- materials were LDPE, HDPE, and PE rubber was sometimes added.

2.) Co-Extruder: CINCINNATI MILACRON, Single Screw 2.5" diameter

- Gearbox, Flender, Type: SDNE 200, Serial# D22-102-238-10-1, Rating 157hp, output 147.8 RPM's, Ratio 11.84

- Motor: 75hp, 225amp drive, 480v/3p/60hz, Powertee-Brushless DC,

- 2.5" Control Panel requires 500amps.

- L:D 36:1 (90" screw processing length)

- Vent side mount located L:D 22:1 (54" length downstream process)

- Screen Changer: 2.5" manual breaker plate

- Connection channel into below head info.

3.) Sheet die Head: Three (3) (opening 54") actual sheet estimate 53"

- Center line of head or sheet discharge height 65"

4.) Calendars (Chilled Rollers)

> 2 - smooth (one not shown in picture) width 54" by 36" diameter

> 1 - texture embossing surface width 54" by 36" diameter

> 1 - top discharge roller width 54" by 24" diameter

- Variable speed on two bottom in feed versus top out feed roller.

- Mezzanine above Calendar for power and chiller with control panel requiring 200amps for chillers with three pumps feeder each of three (3) different chilled rollers. CINCINNATI MILACRON Machine Diagrams # 6005966-103-104-105 and Logic Diagrams: FACTS-0586-E1

8.) Guillotine (shear): 72" cut, Mfg. Famco Machine Co., 10-Gage Mild Steel, Model# P-1072, Serial# S-04956118.

9.) Winder: 64" total roll width, Mfg. Edward Parkinson Mfg. Co., Model# 78-870

10.) Misc. Hopper, Loaders, floor V-rails

Additional information email: ****@gmail.com