Tristate Machinery Dismantlers Forum > WISCONSIN

> Machine Parts

> New

> Without Warranty

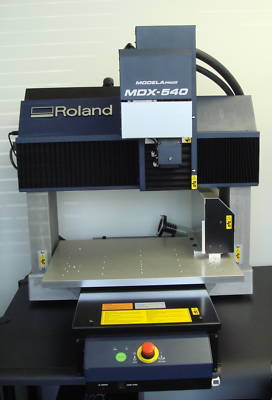

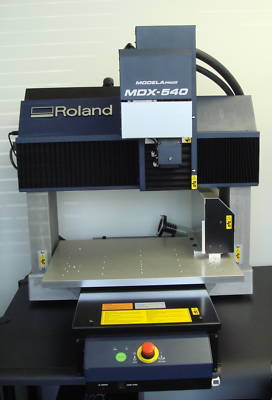

> Roland mdx 540A milling machine

Roland mdx 540A milling machine

* Creates the most accurate prototypes for complex snap-fits

* Creates prototypes for functional testing and proves part manufacturability

* Handles a wide variety of materials and generates a smooth surface finish

* 400W DC Brushless motor with increased torque for fast, accurate prototypes

* Bundled, user-friendly CAM Software

* Handheld controller and virtual control panel make set up fast and easy

* Specialty MDX-540S and MDX-540SA models available for enhanced precision and repeat accuracy

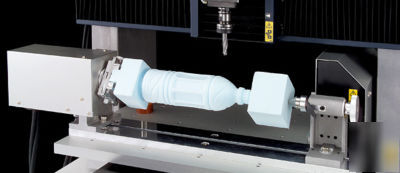

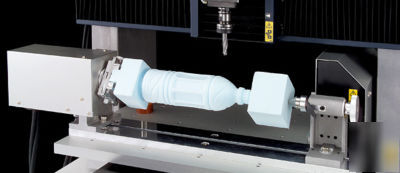

* Optional 4th rotary axis and automatic tool changer

* Maximum 19.68" x 15.74" x 6.10" XYZ-Axis Travel

SRP (Subtractive Rapid Prototyping) - starting with a solid object and removing unwanted material - has several advantages over traditional additive rapid prototyping. SRP devices cost significantly less while producing prototypes out of a wider variety of non-proprietary materials with greater precision and better surface finish.

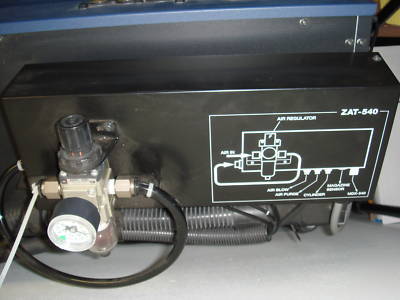

Automatic Tool Changer (Optional)

The Roland Automatic Tool Changer (ATC) further reduces the time and cost associated with product development. From roughing to finishing, this optional accessory enables the MDX-540 to mill prototypes completely unattended. It automatically changes up to four preset tools of different sizes. The ATC comes with an air-activated, high-precision spindle.

The MDX-540 s hi-precision spindle decreases vibration within the unit and produces extremely accurate models, ideal for complex snap-fits. With ISO15448 standard collets, the MDX-540 also generates a smooth surface finish that requires little to no post finishing work.

Roland SRP devices can mill parts in an average time of just over four hours. According to Todd Grimm s independent study of RP systems, the SRP process saves time by producing parts that are smooth and precise right off the machine. Additive systems, on the other hand, typically require time-consuming post finishing processes.

The MDX-540's emergency stop switch enables you to shut down the machine at the push of a button, making it safe to operate in any office environment. An optional safety cover makes the cutting mechanism inaccessible during operation and reduces dust in the surrounding environment. The MDX-540 is also compact enough to fit though standard-sized doors and roll from one room to the next.

Handheld Controller & Virtual Control Panel

The MDX-540 s Handy Panel and Virtual Control Panel simplify both setup and operation. The hand-held control panel can be extended from the machine, allowing you to operate the MDX-540 from a safe distance. It has a jog dial for changing spindle speed and selecting options on the menu. The Virtual Control Panel lets you control the MDX-540 directly from your PC.

Roland's international ISO certification is your quality assurance. Like all Roland products, the MDX-540 was designed and manufactured at a state-of-the-art, ISO-certified facility. Roland builds all products at its advanced Digital Factory one at a time by a single assembler just like a Rolls Royce. Attention to detail is given the highest priority.

Plastic, resin, wood and non-ferrous metals

15.7(X) x 15.7(Y) x 6.1"(Z)[400 (X) x 400 (Y) x 155 mm (Z)]

Loadable workpiece size with optional rotary axis (ZCL-540) *

7.0 Diameter x 14.6 Length [177.8mm Diameter x 370.8mm Length]

Actual milling area is smaller

Distance From Spindle Nose to Table

21.7(W) x 16.5"(D) [550(W) x 420mm (D)]

At acceleration of 0.2G: maximum 26lb (12kg), 0.1G: 44lb (20kg), 0.05G: 44lb (20kg)

RML-1 mode: 0.0004"(0.01mm ), NC-code mode: 0.00004" (0.001mm)

+/-0.004"/12"(+/-0.1mm/300mm), under no-load conditions

+/-0.0019"(+/-0.05mm), under no-load conditions

Origin reproducibility (when the power is switched on/off)

DC brushless motor, maximum 400W

400 to 12,000 rpm; 400 to 3,000 rpm for positioning and centering

Tool holder format, Taper shank: JBS4002 15T

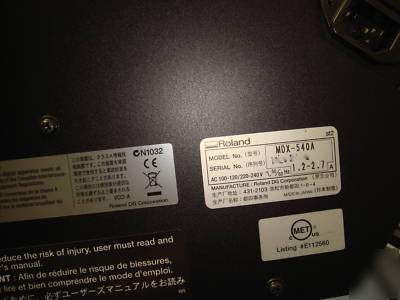

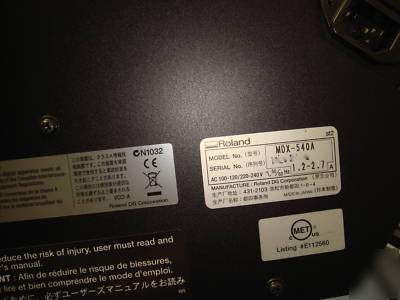

Voltage and frequency: AC 100 to 120 V/220 to 240 V +/-10%, 50/60 Hz

Required power capacity: 7A (100 to 120V)/4A (220 to 240V)

During operation (no cutting): 65dB (A) or less, during standby: 40dB (A) or less (according to ISO 7779)

Width x depth x height: 29.3 x 37.6 x 33.8" (745 x 955 x 858mm)

Handy panel, power cord, tool sensor, sensor cable, nut, nut wrench, wrench, hexagonal wrenches, Roland Software CD-ROM, User's Manual, Roland Software Guide, NC Code Reference Manual, and Automatic Tool Changer (Refer to the ZAT-540 specs below.)

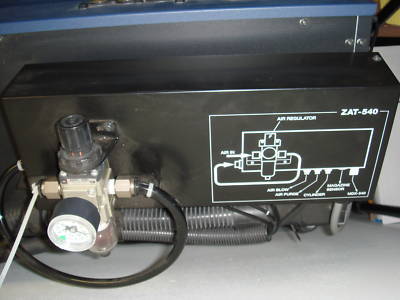

Automatic Tool Changer (ZAT-540)

Direct-changing type, fixed-address specification

102 to 145 psi, 1.8CFM (0.7 to 1.0 MPa, 50 L/min or higher)

15lb (6.8kg) (total weight including spindle, magazine, control box, etc.)

Control box, magazine unit, ATC spindle, air cylinder, base plate, Z-origin sensor, spacer, cap screws, hexagonal wrenches, retaining bands, cable retainers, and user's manual

* When the T-slot table is installed, length is 297 mm (11.7 in.).

When the ZCL-540 is installed, the X-axis travels of the MDX-540 are as follows.

Standard table, no ATC unit: 285 mm (11.2 in.)/325 mm (12.7 in.) (with expanded X-axis travel)

Standard table, ATC unit present: 270 mm (10.6 in.)/325 mm (12.7 in.) (with expanded X-axis travel)

T-slot table, no ATC unit: 218 mm (8.5 in.)/258 mm (10.1 in.) (with expanded X-axis travel)

T-slot table, ATC unit present: 203 mm (7.9 in.)/258 mm (10.1 in.) (with expanded X-axis travel)