Tristate Machinery Dismantlers Forum > INDIANA

> Electrical Components

> New

> With Warranty

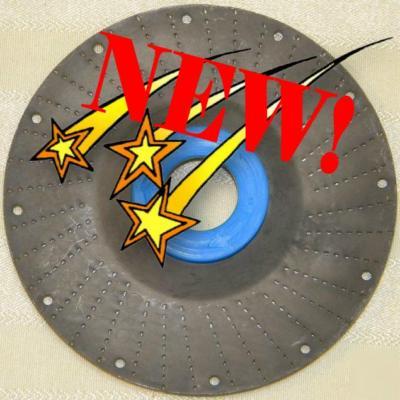

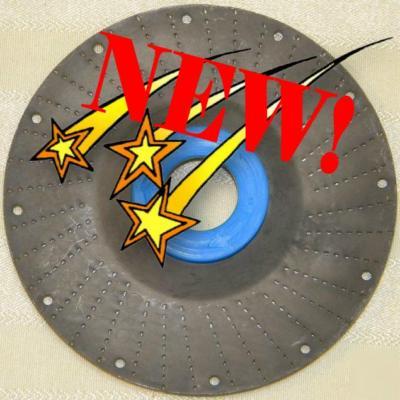

> 4 ½â€X7/8 premium disc grinding wheel last for long time

4 ½â€X7/8 premium disc grinding wheel last for long time

4-1/2" Sanding Disc. LAST for VERY LONG TIME GUARANTEE!

One ROTO Grinding disc changes 30 - 35 Premium Flap sanding/grinding or cutting discs.

* Fiberglass and all other wood fillers

This innovative revolutionary ROTO grinding disc for cutting, grinding and sanding soft materials such as wood, plastic, rubber, Styrofoam, fiberglass etc. by removing particles is used with hand rotation angle grinders. Its construction makes it possible to remove a larger volume, compared to other rotation discs or sandpaper. Its simple installation and do not require special skills or knowledge.

The well-known blades used with angle grinders, such as grinding discs and sandpaper, have certain disadvantages. When cutting soft materials such as wood or plastics with a grinding disc or sandpaper, the removed particles fill the space between the cutting grains, which affects the efficiency of work, increases the friction between the tool and the material, as well as the temperature of the surface you are working on. The filled grinding disc leads to the burned surface and prevents you from further work. The soft material does not allow for the self-sharpening of the blade. A similar problem will appear when using the sandpaper as, except for the above mentioned, it will quickly wear out.The aim of Revolutionary Discs is to widen the range of tools for cutting soft materials by removing particles. Compared to the known blades for angle grinders, the rotation disc makes the cutting of soft materials more efficient with respect to the amount of removed particles in a time unit. The rotation disc can be easily installed by tightening it on its shaft with the original tightening plate and nut. The kinematics necessary for cutting is achieved by changing the rotation on the grinder between 1.500 and 11.000 rpm. Advantages

ROTO GRINDING DISC is made of steel tin, it is 0.7 mm thick and has been thermo-chemically processed. The blades on the working surface of the disc remove the particles and cut. A hole for letting out the removed particles is placed below each line of blades, which prevents the filling of the disc's working area and enables a continuous cutting. Shapes