Tristate Machinery Dismantlers Forum > INDIANA

> Electrical Components

> New

> With Warranty

> Sandvik R390-17 04 12E-pm 1030 carbide milling insert

Sandvik R390-17 04 12E-pm 1030 carbide milling insert

NEW Sandvik R390-17 04 12E-PM Grade GC1030

Will take more wear and tear than you could imagine

The unique multi-layer coating and substrate of the GC1030 earn the grade, top marks for wear resistance and edge-line toughness.

The PVD-TiAIN-coated GC1030 features a balance of compressive stresses that greatly improves edge-line toughness.

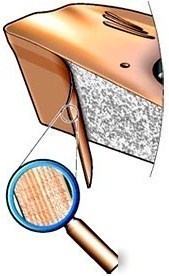

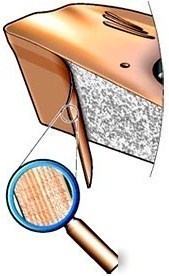

The GC1030 is a bronze-coloured insert for swift and easy wear detection.

The substrate of the GC1030 means the grade can be employed in a broad spectrum of applications.

Taking wear-resistance to the edge

The task we set ourselves was not easy: Increase wear resistance, and edge-line toughness. But when you improve at one end, you often lose out at the other. Something our brief simply would not allow. It said: No compromise! We re pleased to introduce you to a new generation insert from Sandvik Coromant: The GC1030.

Let s say you want to perform end milling, using small cutter diameters. Where it s a question of dry machining or wet. And where conditions aren t as stable as you d like. That s when you ll benefit the most from using our brand new GC1030. The result of extensive R&D, this insert has a unique multilayer coating (please refer to the illustration).

This unique coating means the GC1030 is both more wear resistant and tougher. Put differently: With the GC1030 you can do more titanium milling in less time. And you can machine longer, without changing the insert. It s got to be good.

So please be sure to check my other Items too