Tristate Machinery Dismantlers Forum > MICHIGAN

> Machine Parts

> New

> With Warranty

> Laser edge & centre finder with 1/4 shank

Laser edge & centre finder with 1/4 shank

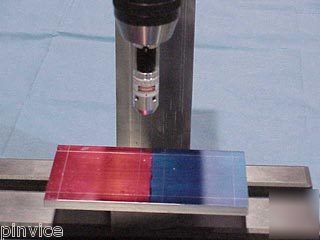

LASER EDGE & CENTRE FINDER WITH 6MM SHANK- NOW WITH POLARISING ATTACHMENT !

ONLY 79.95 INC VAT & CARRIAGE UK MAINLAND

Designed to replace traditional wigglers and mechanical or electronic edge finders

1/4 shank - can be used with the smallest of machines

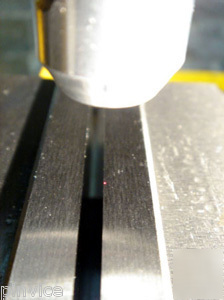

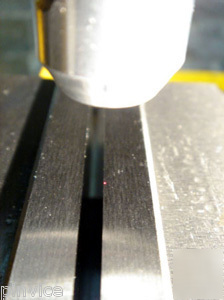

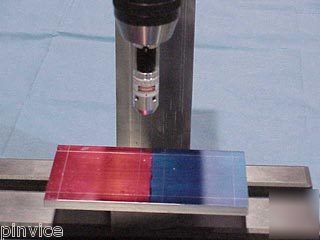

Precision edge finding without readjusting for radius of edge finding tool

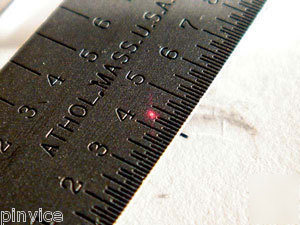

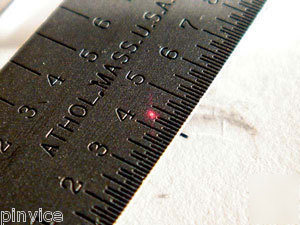

Quickly locate center punch marks or scribe line intersections

Can be used with drill presses, to set mill head angle, realign lathe tailstock after taper cutting, lathes with 4-jaw chuck setup or to align the vice on the mill table.

The Laser Center/Edge Finder is a new tool for your mill that will save setup time. For the new Home Shop Machinist it will eliminate the frustrations and doubts of learning the century old Indirect Method with the conventional Edge Finders or Wiggler.

The Laser Center/Edge Finder is a Direct Method center or edge finder. Current Center/Edge Finders are Indirect Methods. Current Finders require the Mill operator to determine where the edge of the material is by imposing sufficient pressure on the finder to just slightly bump the material and then move over one-half the diameter of the edge finder to locate the true edge of the material. Another accepted method is a center/edge finder that has a spring loaded conical disc that kicks sideways when touching the edge of the material and the Mill operator then moves the mill table over one-half the diameter of the edge finder to locate the true edge of the material.

The mechanical/electrical center/edge finders function as the mechanical ones do except that instead of a spring loaded offset disc it utilizes electrical continuity to determine when the edge finder has contacted the material (not always useful on non-conducting material). The Mill operator hears an audible signal or a light comes on indicating contact has been made. The operator must still add half the diameter of the edge finder to determine the true edge of the material.

The Laser Center/Edge Finder only requires the Mill operator to move the table under the small Laser beam until the laser light shows that the light is at the edge of the material to locate the true edge of the material. If the Mill operator is attempting to position the Mill quill to a Center Punched mark on the material, the table is moved until the laser light centers on the punched mark. In both instances this Direct Method eliminates the most common mistake of forgetting to add half the diameter of the conventional center/edge finder to locate the true edge of the material.

LASER MODULE: Class IIIa (<5 mW) 640-660nm 4.5v

BEAM SPOT DIAMETER: 0.1mm-0.5mm (Dependent on surface reflectivity)

BATTERIES: LR44 1.5V (3X) (batteries included)

OR CUT AND PASTE THE FOLLOWING INTO YOUR TOOLBAR TO VIEW A SHORT VIDEO DEMONSTRATION

http:// /video2.html