Tristate Machinery Dismantlers Forum > MICHIGAN

> Machine Parts

> Used

> With Warranty

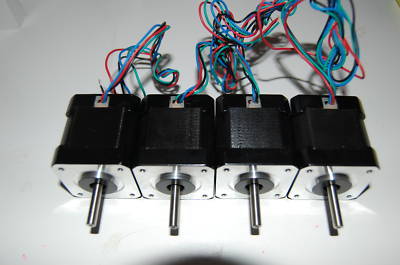

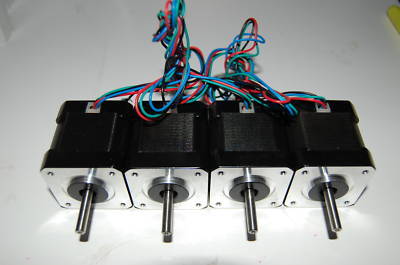

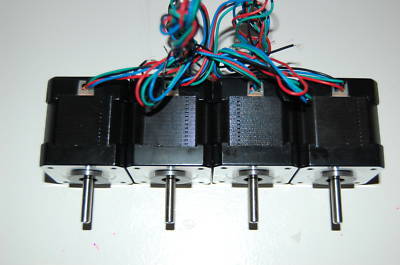

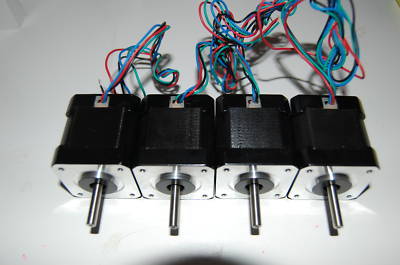

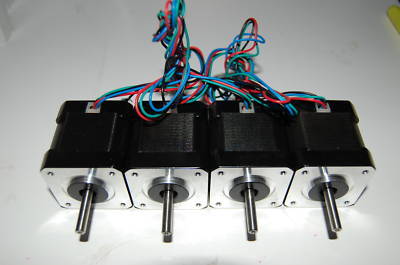

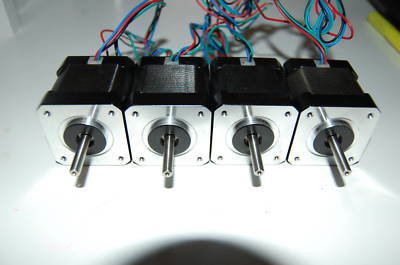

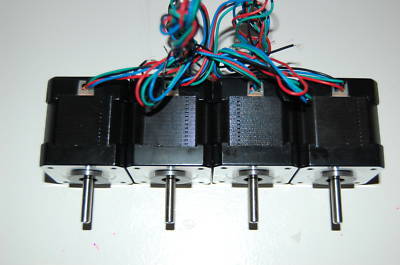

> Qty (4) reprap mendel stepper motors NEMA17 75 oz/in

Qty (4) reprap mendel stepper motors NEMA17 75 oz/in

These are NEW steppers that meet all specs for Mendel II reprap. These are the larger motors with extra holding torque to minimize heat and maximize speed. These motors are NEMA 17. Keep checking back I will have other kits and sub assemblys for reprap Mendel. Below is info from reprap.org

Your RepRap machine will need three (3) stepper motors for the 3 dimensions. In addition, you might use a stepper based extruder.

These are the general requirements so far for a RepRap machine. You could probably get by with less, especially for the lighter X axis, but this is what we recommend. Always choose a high torque motor for the extruder.

about 10 ohms, or 1 to 30 ohms

If you are using the PIC controller you need a motor that will use about 1A per winding at 12v, that is - around 10 ohms. The Arduino circuit can be adjusted to accommodate a wider range of steppers, but remember that if you specify a low-resistance one and the Arduino controller has to chop the voltage to limit the current going through it, that will also limit the torque.

It is recommended that you get approximately 13.7 N-cm (that is 1400 g-cm or 19.4 oz-in) of Holding Torque (or more) to avoid issues, although one stepper with less has been used successfully (see below). If in doubt, higher is better. If you need to convert between different units for the torque you can use the torque unit converter here.

Most stepper motors used for a Mendel have a step angle of 1.8 Degrees. It is sometimes possible to use motors with larger step angles, however for printing to be accurate, they will need to be geared down to reduce the angle moved per step, which may lead to a slower maximum speed.

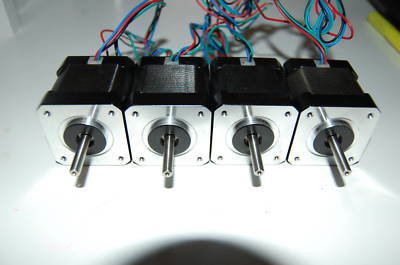

If going for the smaller NEMA 14 motors, aim for the high torque option. NEMA 14s are neater, lighter and smaller, but can be hard to get hold of with the appropriate holding torque. NEMA 17s are quite easy to get in the specification that Mendel needs, but are bulkier and less neat. NEMA 14s are running near the edge of their envelope: they will get warm. NEMA 17s are well inside what they can do, and will run much cooler.

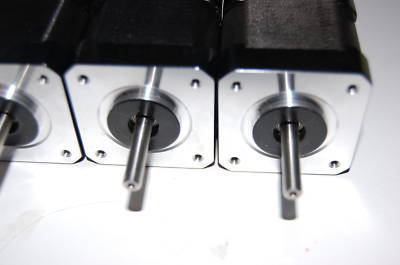

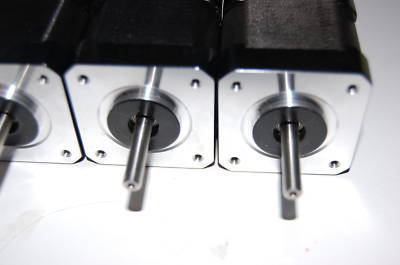

Note that any Mendel part that goes on to a Stepper Motor shaft expects the shaft to be roughly 5mm. If the shaft is a different size, you will need to make allowances for this in the parts you obtain/make.