Tristate Machinery Dismantlers Forum > STATE OF IOWA

> Electrical Components

> Used

> Without Warranty

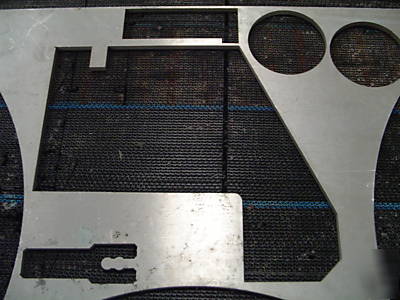

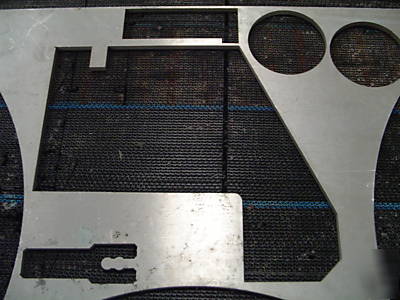

> Cnc water jet machining 6" thick solid steel A2 D2 dies

Cnc water jet machining 6" thick solid steel A2 D2 dies

WATER JET MACHINING AT OUR JACKSON, MI PLANT.

Because waterjet cutting is more productive than other cutting methods, you can eliminate secondary processes and produce high quality parts, the first time. Because there is no heat or chemical impact to material, material yields are greatly improved. And, you can stack thin materials or cut materials up to 6 inches thick, with no tool changes. Straight cuts, holes, curved corners and even contoured cutting are accomplished easily.

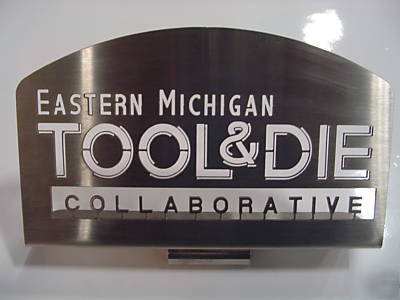

Steel, Aluminum, Plastic, Armor Plate, Plywood, Rubber, Porcelain China, are just a few of the materials we have cut with out water jet.

The waterjet cutting process is quite simple. Water is pressurized to 60,000 PSI by hydraulic intensification, and then forced through a small orifice in the cutting head. Inside a mixing tube, abrasive is mixed with the high pressure water, creating an abrasive waterjet stream that exits the nozzle at about 1.5 times the speed of sound. Through a combination of micro-erosion (grinding) and a shear yielding of the material a narrow section of material (called the kerf) is removed all the way through the thickness.

WE WOULD BE HAPPY TO QUOTE ANY JOB FOR YOU!