Tristate Machinery Dismantlers Forum > STATE OF IOWA

> Machine Parts

> New

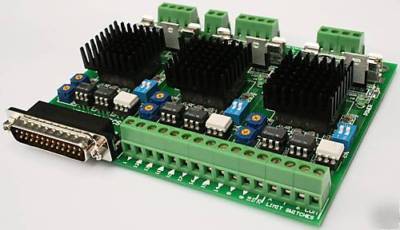

> 3 axis stepper motor controller cnc router or mill

3 axis stepper motor controller cnc router or mill

Made with Top Surface Mount Technology

Two phase bipolar (PWM Technology) this board doesn't need any external resistor for current motor adjustment.

Resolution (Full step, 1/2 step, 1/4 step, 1/8 step) selectable via dip switch for each axis, also, you can get a resolution of 1600 steps per 360 revolution with a conventional 200 steps motor, Imagine the fine movement that you will get!

2.5A motor current capacity per phase, in every axis

Individual axis enable/disable, via optocoupler input terminal (can be used as limit switch)

Full Adjustable stepper motor current via potentiometer on board

DB25 MALE connector on board for PC parallel port

All inputs signals are optocoupled for PC parallel port protection

Full access to all unused DB25 pins connector via terminal block, easy connection for prototyping work

24VDC @ 2-to-6 amp power supply required, 12VDC as minimum, 32VCD as maximum

4 Wire, 6 Wire and 8 Wire (NEMA 17, NEMA 23, NEMA 34) Bipolar or Unipolar stepper motors can be used with 3 axis drive

Fuse integrated for electrical protection

Individual heat sink per axis. Every IC driver and optocoupler are mounted in socket, you can replace them if they're damaged in just 5 minutes!.

The motor current is adjusted with the potentiometers on board. You can configurate the stepper resolution with the Dip Switch on board, also, the configuration table is printed on board.

Fuse integrated per axis, as electrical protection. This fuse protect the printed circuit board tracks in case of short circuit. Power LED on board per axis.

DB25 MALE connector, ideal for your PC parallel port. Enable switch per axis and breakout for unused DB25 pins, ideal for prototyping work.

DRIVER BOARD USER MANUAL AVAILABLE HERE