Tristate Machinery Dismantlers Forum > WISCONSIN

> Motors and tools

> Used

> With Warranty

> Leybold aps 1104 coating machine

Leybold aps 1104 coating machine

Leybold APS 1104 vacuum coating machine is in excellent working condition. Seller gurantee the machine's performance both for mechanical and for coating process. Seller also provide the following service:

1. De-installation service at seller's facility (free).

2. Packaging the coater and loading the coater into the container or truck (free).

6. 90 days warranty for free labor, and parts 50% off of the original Leybold vaccum parts.

The whole coating system includes the following:

Major components of Leybold APS 1104 (mm) optical coating system.

Major component of Leybold coater is listed as the following:

+S1 Vacuum chamber/pumping port: 2000kg, 1450x2024x2350 mm3

+K1 Electrical cabinet: 500kg, 1340x700x200 mm3

+K2 Electrical cabinet 2: 250kg, 725x570x2000 mm3

+9 Electrical cabinet APS: 250kg, 800x600x2000 mm3

+L1 Power division: weight 200kg, 262x820x820 mm3

+G1 Plasma power supply: 210kg, 780x660x880 mm3

+E1 Polycold: weight 480kg, 1540x711x1689 mm3

+A1 High voltage supply: 500kg, 600x600x1200 mm3

All components are original and have been kept in good working condition and no replacement for any of these components.

Function of the Leybold APS 1104 (mm) optical coater

Leybold APS 1104 currently can hold substrate of 300 mm easily, and with modification, the substrate size can be any where from 1 mm to 800 mm in diameter. The substrates materials can be glass, ceramic, metal, special molded plastics and special materials.

It has the substrate fixture as a high speed single rotation type as shown in the picture. The fixture is hanging on a 12 inch diameter bulky ferro-fluid sealed feed-through. The high speed motor single rotation can hold 300 mm substrate to rotate at the speed of 1200 RPM, and hold 700mm diameter substrate with the weight of 100kg to rotate at the speed of 300 RPM or above without any issue. In addition to this single rotation fixture, the system also has dome shape substrate holder to hold parts in general optics coating applications. The dome substrate fixture rotation speed can vary from 0 to 500 safely without any issue. This can be confirmed with the original system builder, Leybold Optics in Germany.

The coater was purchased solely for the purpose of making precision optics filters. Since its purchase in 2001, the only materials used in this coating unit are Ta2O5, Nb2O5 and SiO2. No other materials have been used in this system.

Thin film deposition equipment

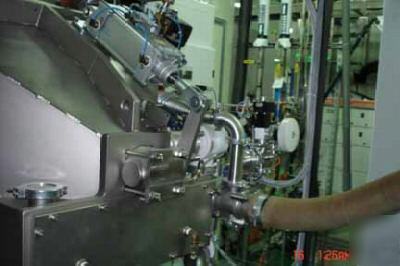

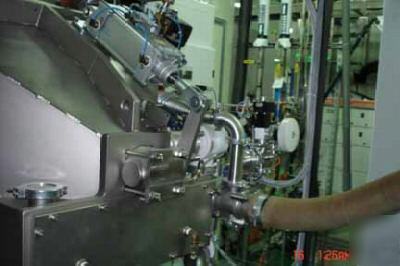

The coater unit has two e-beam guns, one EVQ/14 e-beam gun and one ESQ212, and one Leybold advanced plasma source for assisting for the film deposition. All of these work properly in excellent condition.

Leybold pumping component are equipped with roughing, high vacuum, and ultra-high vacuum pumping systems. The roughing pumps are Leybold double stage pumping with Leybold D65B mechanical pump, and WRUS 501 second stage mechanical pump. Diffusion pump is Leybold DIP12000 and the ultra-high (water vapor pumping) pump is Polycold PFC-1101HC. All of these pumping components are in good working conditions.

It s APS source can be used both for deposition assist and also substrate cleaning. It is the most effective mechanism in the scale of atomic level scale to clean substrate. Leybold optics has been using APS as its main technology in coating business and APS has earned its name in the industry.

The coating unit has three gas systems which can be controlled very precisely to the 0.1 sccm resolution. The three gases are controlled separately and they are Ar, O2 and N2 for venting. N2 venting is an optional so the system is also equipped with ambient air venting system on the top back of the machine.

The coating unit has two water cooling systems. Both are for cold water and for the whole system including chamber, e-beam source, APS and all the ferro-fluid feed-through connections. The chamber is also equipped with hot water cooling for the purpose of avoiding condensation when the chamber door is opened for load and unload the substrates. This hot water cooling function is only an option when the

coating chamber environment is not under temperature and humidity not controlled.

Pressure, inlet: 5 to 7 bar absolute (73 to 102psig)

Temperature inlet: 15C to 25C/ 59F to 77F

Drain: free drain, pressure drop in outlet max. 1.5 bar absolute (22 psi)

Temperature inlet: 40C to 60C/104F to 140F

No LN2 is needed for the pumping of the system since the system has a polycold pumping. However, LN2 can be used for venting the chamber after the coating process.

The coating unit is equipped with shutters fully for 2 e-beam sources separate, for APS source and for substrate as well.

The coater control system is Leybold Leycom IV, user friendly Leybold computer system, which is not micro-soft window based software. However is well organized, clearly categorized and easy to be operated and visualized. The control is through a computer monitor with push buttons right next to the computer screen.

The coating system has an operating system well done. The system can be run manually, and also can be put into the auto mode. An operator can program the machine a day ahead or a week ahead of the time and the system will start run according to the operator s program.

The main controllers of the coating system are the following:

Leycom IV for system process control

OMS control box to control optical monitoring system 3000 (Optional)

APS controller to control APS operation.

XT/2 controller to control quartz monitoring system

Operator interface is Leybold Leycom IV computer screen and controller screens listed in above section. Leycom IV can also allow an external computer to be connected to the machine s control system to view the operation, especially the optical monitoring process.

The current coater system does not have a RGA system equipped into the system but there are at least two flange type CF40 for the RGA unit.

The coating system currently has a 6-fold quartz monitoring system for film thickness growth monitor.

The Leybold APS system has the following dimensions

Chamber Size: 1104 mm diameter

Total system height with the high speed motor on top of the chamber roof: 2650 mm

Chamber area coverage: 4600 mm x 2950 mm

Chamber operational area coverage: 4320 mm x 4600 mm

In order to have a comfortable working space on the system, 5000 mm x 5000mm x 2650 mm cubic space should be allocated to the coating unit.

All component and the parts are mechanically operational against the coater s original manufacturer spec. which is Leybold Optics, Germany.

The Leybold coating system uses power of 400Volts, with maximum of 160 amps. 3 phase

Specification: dry, no oil or grease

Pressure: 7 to 9 bar absolute (102 to 129 psi)

LN2 vaporized N2 gas will be used for the venting chamber in the coating process.

Original Leybold APS 1104 manual attached to this coating system to show all the safety procdedure.

The Leybold APS 1104 coating machine has its name for reliable and repeatable and high vacuum

pump diffusion pump DIP12000 is almost maintenance free. It can be used for 8-12 months without servicing. For machine maintenance, a complete original Leybold coater manual will be enclosed with the coater.